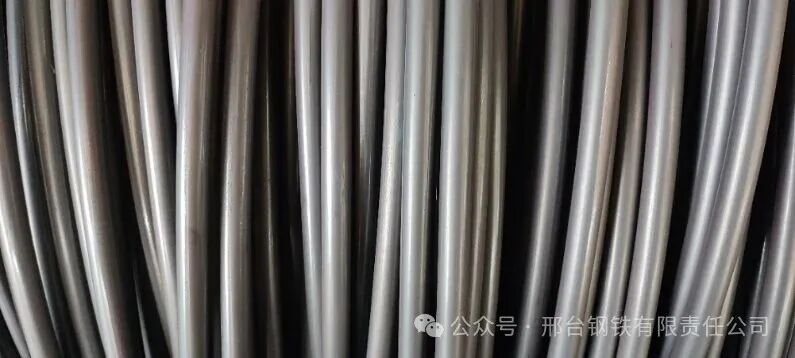

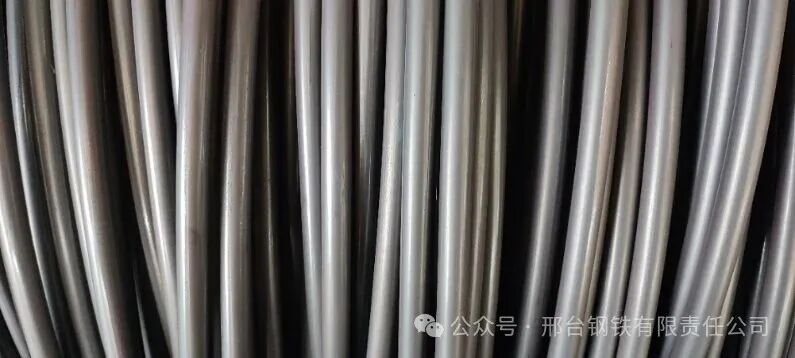

Bearing steel, a critical steel grade characterized by high technological content and considerable production difficulty, is hailed as "the pearl on the crown of special steel". China’s domestic bearing steel market boasts a broad capacity. Among market players, Xingtai Iron and Steel has long ranked among the top in sales volume in the wire rod segment of bearing steel. Its high-carbon chromium bearing steel wire rod products are widely used in the manufacturing of bearing components, ultimately serving key industries such as automobiles, home appliances, engineering machinery and machine tools.

With industrial upgrading and evolving market demands, downstream customers have put forward higher requirements for high-end bearing steel wire rods. In particular, strict standards must be met in terms of non-metallic inclusion control, carbide network and banded structure, which need to reach the advanced or even premium quality levels specified in national standards.

To enhance the brand influence and market competitiveness of its high-end bearing steel, Xingtai Iron and Steel’s Technology Center, in collaboration with the Steelmaking Plant and Wire Rod Plant, has carried out a series of process optimizations and technological innovations focusing on key production procedures, with priority given to overcoming core challenges such as large-size inclusion control and carbide segregation. At present, the products have achieved full compliance in key quality indicators including non-metallic inclusion rating, carbide network and banded structure in the annealed state, and surface decarburization, with their quality level improved remarkably.

Moving forward, Xingtai Iron and Steel’s Technology Center and Sales Company will closely follow up on user feedback, continue to drive quality improvement and process optimization, and provide data support for the iterative development of high-end bearing steel.